iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® W300 has excellent wear resistance and even withstands rough shafts.

iglidur® W300 has excellent wear resistance and even withstands rough shafts

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® R is very resistant to wear and runs with low coefficients of friction during dry operation. Due to low moisture absorption, it is resistant to dirt, water or chemicals and can withstand low to medium loads

iglidur® R is very resistant to wear and runs with low coefficients of friction during dry operation. Due to the low moisture absorption, it is resistant to dirt, water or chemicals and can withstand low to medium loads.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

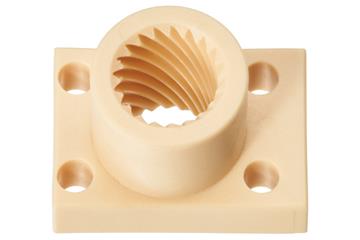

Quick release mechanism: a combination of accurate positioning and fast manual adjustment with trapezoidal lead screw nuts

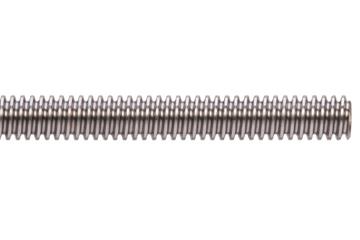

dryspin® technology, left-hand thread

dryspin® left-hand thread

dryspin® left-hand thread

dryspin® left-hand thread

dryspin® left-hand thread

dryspin® reverse thread

dryspin® reverse thread

dryspin® right-hand thread

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.

iglidur® J350 is suitable for high temperatures and low coefficient of friction at medium load.

iglidur® J350 is suitable for high temperatures and low coefficient of friction at medium load.

iglidur® W300 has excellent wear resistance and even withstands rough shafts.

iglidur® J350 is suitable for high temperatures and low coefficient of friction at medium load.

iglidur® J is used for high speed and low wear, but also for best coefficient of friction.