Change Language :

P4.1 rol e-chain®

The P4.1 series of rol e-chains allows for increased system safety and availability. Each chain link connection contains a bearing point for a pivoting movement. These have now been redesigned with maintenance-free plain bearings made of high-performance polymers, which has more than doubled their service life.

- Longer service life - 375,000km running performance - thanks to maintenance-free tribopolymer plain bearings in chain link connections

- Long travels of over 1,000m

- Speeds of more than 5m/s

- Low vibration and travel noise thanks to split profile roller

- Integration of sensors for intelligent condition monitoring

- Guarantee of up to 36 months on energy chains and cables or alternatively the number of double strokes determined by the service life calculator

Your requirement

Increased system safety and availability

To meet the growing demands of new container ships, such as those in the Triple-E class, new and larger STS cranes must be built or else existing ones converted. In addition, the requirements for crane availability and reliability are increasing. This also has an impact on the design and selection of the energy supply system.

Our offering

Next-generation P4.1 rol e-chain

To increase availability and reliability of STS cranes, igus has developed the P4.1 rol e-chain. Here, tribologically optimised plain bearings ensure lubrication-free support for the individual chain links. This more than doubles the chain's service life. An optional sensor also allows for predictive maintenance, which further increases system availability. Highly flexible cables from the chainflex product range complete the fail-safe solution for cranes and long travels. The P4.1 system is suitable for both trolley drive and longitudinal travels of 1,000m and more.

Free white paper:

Triple-E-class container ships and the energy supply requirements of STS cranes

This white paper addresses the following topics, among others:

- Challenge: cranes for Triple-E-class container ships

- Requirements for crane availability and reliability

- Comparison of energy and signal supply systems for crane trolleys (festoons, busbar systems and energy chains)

- Technological outlook: rol e-chains

Service life comparison* igus rol e-chain generations

*The stated running performance data results from extrapolations of customer applications in combination with our test data.

Special features of the P4.1 rol e-chain

Reduced coefficient of friction and drive power

Due to the offset between the upper and lower run, the plastic rollers do not roll over but past each other, allowing for particularly smooth operation. This reduces the coefficient of friction and drive power by 57%.

Longer service life

The energy chain's service life is more than doubled thanks to maintenance-free plain bearings in every chain link.

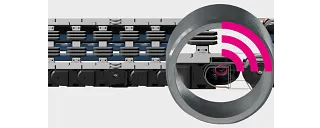

Predictive maintenance

The new P4.1 can be equipped with smart monitoring sensors as an option. They send a signal to the igus i.Cee communication module when a defined wear limit is reached, so that predictive maintenance of the rol e-chain can be planned in advance.

P4.1 rol e-chain® for long travels over 1,000m

Test for long travels

The rol e-chain was tested with a travel speed of up to 8m/s over a distance of 200m, which corresponds to a 400m travel. The fully automatic system accounts for a wide range of applications in terms of acceleration and speed. In addition to the mechanical loads caused by the movement of the transfer vehicle, environmental influences act on the energy chains and cables being tested.

Assembly instruction for P4.1 system

Quick and easy assembly and disassembly of the P4.1 energy chain

Joining:

- Press the chain links together

- Tighten screws with screwdriver

- Install autoglide crossbars

Disassembly:

- Dismantle autoglide crossbars

- Remove screws with a screwdriver

- Separate chain links

More information

ASI Automatikk AS Distributor+47 9006 1100