Change Language :

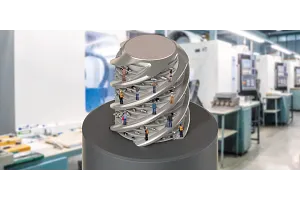

Free dryspin high helix lead screw sample

Lubrication-free lead screw technology

Tools & lead screw technology configurators

dryspin lead screw technology offers a range of online tools to help users find the right lead screw drive solution for their application requirements. These comprehensive tools identify suitable products based on the parameters entered, predict the service life and generate 2D and 3D CAD models. Systems can also be customised, which simplifies the design process. The final configurations can be saved or added directly to the shopping cart.

The dryspin lead screw technology at a glance

FAQ lead screw technology: Frequently asked questions

The dryspin lead screw technology is available in five different thread types: trapezoidal thread, high helix thread, sliding thread, ACME thread and metric threads. The decisive difference between the individual thread types lies in their thread geometry and the respective areas of application.

Each variant has specific advantages in terms of self-locking, fine adjustment, running behaviour and efficiency. We provide a compact overview and show when which lead screw is the best choice.

The dryspin lead screw technology is used wherever efficient, quiet and maintenance-free linear movements are required. Typical application areas include:

- Automation technology - e.g. in adjustment units and linear systems

- Medical technology - ideal for sensitive environments thanks to quiet and lubrication-free operation

- 3D printing and laboratory equipment - precise positioning in installation spaces

- Furniture and furnishing technology - for height-adjustable tables or actuators

In addition, dryspin is represented in many other sectors, such as automotive, railway technology, construction machinery, boats, camera technology, food industry, aerospace, packaging industry, etc.

👉 To all fields of application of dryspin lead screw technology

igus is pursuing the goal of CO₂-neutral production by 2025 - also in lead screw technology. The dryspin lead screw nuts are made of wear-resistant high-performance plastics that do not require external lubricants and therefore avoid environmental pollution. Thanks to efficient production, plastic lead screws consume up to 50% less energy than comparable metal solutions.

igus also favours short distances and reuse when it comes to packaging, storage and transport. In this way, igus combines durable, maintenance-free products with a clear sustainability claim.

Holding a sample in your hands gives you a comprehensive impression of the product. We will be happy to send you one of our high helix thread samples.

Your own lead screw sample with summarised information

- Lubrication-free and maintenance-free

- Higher efficiency

- Longer service life due to asymmetry

- Media-resistant

- Low-noise, vibration-free operation thanks to rounded tooth geometry

- Service life predictable online

👉 Request high helix thread samples here

Customised samples are also available. Just get in touch with us!

The maximum recommended lengths for lead screws are generally between 500mm and 3000mm. The ideal length depends on various factors, such as the lead screw diameter, the application speed, the load and the installation position.

Longer lead screws can lead to resonance effects at higher speeds.

- Higher efficiency

- Quiet and low-vibration operation

- 30% longer service life due to asymmetry

- Up to 25% less wear

- Higher efficiency

The test evaluation of the wear test of the 10x3 stainless steel dimension has shown that our dryspin thread Ds10x3 can achieve up to 25% less wear rate, up to 25% longer service life and higher efficiency compared to the competition and the trapezoidal thread Tr10x3.

The lead screws are available in the following materials:

- Stainless steel 1.304 for high corrosion resistance

- C15 steel as a cost-effective alternative

- Aluminium when a non-magnetic material is required

The lead screw nuts are available in various igus high-performance plastics, including:

- iglidur J - our most widely used material with very good all-round performance

- iglidur J4 - our most cost-effective solution

- iglidur J350 - for applications with high temperatures up to 180°C (350°F)

- iglidur A180 - FDA-compliant, suitable for use in the food industry

- iglidur R - with particularly good vibration dampening

- iglidur W300 - for high static loads and simple manual adjustments

- iglidur E7 - for light loads at very high travel speeds

👉 Learn more about the materials and their specifications here

The DST thread geometry

2013

The patented dryspin high helix thread technology was developed by igus in 2013 and offers numerous advantages compared to conventional high helix threads. Due to the flat thread angle, it efficiently converts the force introduced into a linear movement. With specifications and geometries matched to the plastic nut and lead screws, dryspin provides an even longer service life and more efficiency for high helix threads.

USP1

Due to the larger distances between the individual dryspin thread turns, the thread perfectly matches the specifications of the lubrication-free igus high performance polymers. The proportion of the tribologically optimised polymer in the thread turns can be enhanced by a factor of 1.3 for all sizes. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to standard thread geometries.

USP2

Due to the rounded tooth geometry, the contact surface between the lead screw nut and the lead screw is reduced. This is due to the fact that the greater the contact of two surfaces moving against one another, the more vibrations are transmitted, which can be perceived as a rattle or squeak. The rounded teeth minimise this effect and the thread moves vibration-free and virtually noise-free.

USP3

Our lead screw systems are developed for maintenance-free dry operation. Basically, you should not compare a lubricated lead screw system one-to-one with a dry-operating system. Due to the external lubrication, the coefficient of friction is lower compared to a dry-operating lead screw system. However, the lubricant also causes a high maintenance effort and additional costs that are often not accounted for.

Application examples

ASI Automatikk AS Distributor+47 9006 1100