Change Language :

Which e-chain with extender crossbars should I choose?

The application case described here for Westphal in 2002 was the starting signal for the further development of energy chains with extender crossbars, which we now have in different versions in our standard product range. You can find out which chain is the right one when it comes to guiding hoses in CNC processing machines in the application case relating the manufacturer Trima:

▶ Find out now

Energy chain with suction hose in piggyback

A new type of energy supply system created from standard components

Special construction or standard solution? Customers want technically optimised machines without special design problems such as time-consuming spare parts procurement and high development costs. What initially looks like squaring the circle can be achieved, as Westphal Maschinenbau, based in Hamelin, Germany demonstrates with igus components. A new type of energy supply system was created from standard parts, and its piggyback principle finally gives the large-volume suction hoses in wood and sandwich processing a defined place and creates space for refinements.

"Skirting around the problem has come to an end"

Large suction devices for extracting swarf are characteristic of wood, aluminium profile, and sandwich element processing. But suction hoses hanging from the ceiling were simply not feasible if machines were to be increasingly modern and continue to deliver higher performance. A solution was urgently needed. "It gets tricky even with just two hoses," says Westphal describing the problem. "So we looked around the market for a solution." And they did it with characteristic Westphalian openness. Westphal wanted its energy supply system supplier to be as competent and transparent as it is with its own customers. "We were immediately impressed by the igus sales engineer. He came right away and submitted a qualified quotation within a few hours. And when questions arose during installation, he came and supported us. We now have a solution that puts an end to skirting around the problem and enables us to refine our machine however we want – with more axes (absolutely or per linear robot) and longer travels."

So what exactly was the solution?

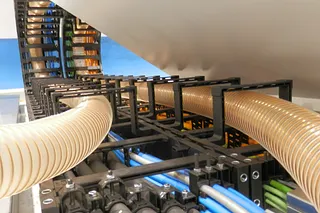

The collaboration between Westphal Maschinenbau and igus has resulted in a piggyback solution with the energy supply system type 1600.40.250.0. It is made entirely of plastic and does not require any metal screw connections. This makes it particularly gentle on cables and hoses. It

- reliably separates the large, relatively fragile hoses on one side of the energy supply system from the pneumatic and energy cables on the other side.

- guides large hose diameters - in this case 250mm - with a minimum amount of material and therefore low weight.

- is based on the modular energy supply system from igus, which ensures the supply of spare parts.

"In fact, this solution is only possible with our modular system," says Michael Blass from igus. "With over 43,000 parts, we can also implement special solutions from the modular system. Here we have rearranged standard components so that the customer has no waiting times when reordering."

Option for the future

igus energy supply systems play a major role in the flexibility and expandability built into Westphal machines. "These systems are what allows us to achieve optimal hose and cable guidance with several axes and linear robots," says Westphal. "Customers want plug-in machines – preferably with a central supply for all connection cables (data, energy, compressed air, and extraction). "Increasing performance is another trend: Westphal is already using machines with three independent linear robots and 12 axes. And that's not nearly all. Up to 16 axes and travels of up to 40 metres are already being planned. The large number of supply lines make such large, complex systems unthinkable without powerful energy supply systems. This opens up new areas where Westphal Maschinenbau GmbH and igus GmbH can cooperate successfully.

Here you can find the products used

ASI Automatikk AS Distributor+47 9006 1100