Change Language :

igubal innovations

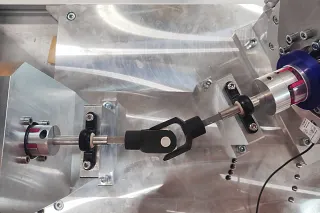

First prototype of our plastic universal joint

With the new UJM plastic universal joint, we present an innovative alternative to conventional metal solutions. The prototype for a 10mm shaft shows how efficient lightweight construction can be: corrosion-free, lubrication-free and with clear advantages in terms of weight, maintenance and costs.

Thanks to optimised geometry and FEM analysis, the joint impresses with its high strength and a transmittable torque of 6Nm at 25° deflection - tested in the igus laboratory. Other sizes and more compact types are conceivable. Do you have a specific application? Then contact us - we will develop the right solution with you.

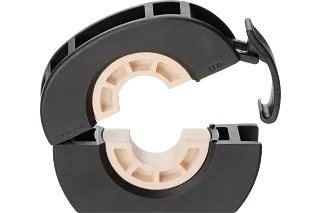

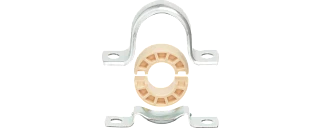

Now available: Pillow block bearing with quick-release

Tool-free spherical insert bearing change in seconds – the new quick-release pillow block bearing is here. Following a successful prototype phase, the injection moulding version is now ready for batch production and available with no minimum order quantity – currently for a shaft diameter of 25mm.

The spherical insert bearing can be replaced without screws or tools – in just one easy step. This saves time, reduces downtimes and lowers maintenance costs. Tested in the igus laboratory: up to 9kN static pressure load, 100% lubrication-free operation and ideal for modular system concepts in which components need to be adapted flexibly and quickly.

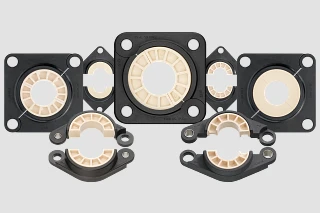

PTFE-free materials for the igubal series

Sustainable designing - without compromise.

With iglidur J3, iglidur R and igumid G, we offer completely PTFE-free materials for the entire igubal product series.

Tested in our in-house laboratory in accordance with SQP M1227 and tested negative for 96 particularly critical PFAS compounds.

Whether rod ends, pillow block bearings, flange mounted bearings or spherical bearings: our shop only shows a selection of the possibilities. Special dimensions can also be realised - just contact us. Together we will find the right solution for your application.

igubal 2.0 – Metallic rod ends with plastic inner ring

With the igubal® 2.0 rod ends, we offer maximum flexibility for a wide range of applications. Four iglidur materials, all common thread types and shaft diameters from 6–20mm: The combination of robust metal housing and lubrication-free plastic inner ring enables long-lasting, maintenance-free solutions – without any lubricant.

| Material | Area of use |

|---|---|

| iglidur J | High wear resistance |

| iglidur A181 | FDA and EU 10/2011 conformity |

| iglidur X | Wide temperature range (-100°C to +250°C, short-term up to +315°C) |

| iglidur G | Dynamic loads |

NEW | White paper on our split flange mounted bearings

Our split igubal flange mounted bearings are revolutionising shaft bearings in confined production environments. Save up to 80% time when changing bearings and benefit from complete freedom from maintenance thanks to the absence of lubrication.

Discover in our white paper how advanced bearing technology increases your machine performance and effectively prevents downtime.

Download white paper now!Split flange mounted bearings and spherical insert bearings

Direct bearing replacement on the shaft - without conversion work!

Our split flange mounted bearings enable direct mounting on the shaft without dismantling other machine elements. This efficient solution saves time and money, especially in bearing positions that are difficult to access. Manufactured from high-quality high-performance polymers, they are extremely light, robust and maintenance-free, which further reduces operating costs.

After introducing the split F208 and FL208 versions last year, we are expanding the product range this year to include the compact 208 versions. These work with the pitch dimensions of the 206 series and are available for shaft diameters of 40 mm and 30 mm.

Split spherical insert bearings for PP205 pillow block bearing

Quick replacement

Our split spherical insert bearings for PP205 sheet metal housings enable quick and easy replacement of the spherical insert bearing directly on site without having to dismantle other components. They offer simple and efficient installation as well as significant cost savings when changing bearings thanks to the quick replacement. With a static tensile load of up to 1,800N and no need for additional lubricants, these spherical insert bearings are the ideal solution for efficient and maintenance-free bearing support.

Injection-moulded spherical insert bearings made from iglidur H3

3D-printed prototype of the ESQM-2.0-120-HD put to the test

Heavy duty pillow block bearing | Study

Heavy fun with the Sun

This study tests the performance and applicability of the heavy-duty ESQM for the solar industry.

The ESQM 2.0 heavy duty is a further development of the ESQM 2.0 and was specially developed for extreme weather conditions, e.g. tropical storms. It consists of a split housing and two spherical ball half shells. The spherical ball and the housing base are made of plastic with high UV resistance. The redistribution of the wall thicknesses at load points and the doubling of the bracket thickness make the bearing 50% stronger. Another variant with a hard stop, which we have tested, prevents unauthorised rotation of the tracker axes and protects both the axis and motor from damage.

Further innovations

Don't miss any more igus news

With our motion plastics news you won't miss any news about igus and its products. Our newsletter will keep you up to date: new products, exciting applications, current laboratory reports and much more.

More about igubal spherical bearings

Shop

Are you familiar with our products and would you like to view the selection in the online shop or order directly?

Tool

In just three steps, you can use the parameters of your application to determine suitable product recommendations, including service life.

Knowledge Base

Here you will find the most important information, technologies, questions and answers about igubal spherical bearings.

The possible applications for our products are as diverse as our customers' ideas!

The manus competition 2025 has once again demonstrated how versatile the igubal series is in a wide variety of projects, mastering technical challenges in the process.

We have compiled the 20 most exciting applications for you in a digital magazine – full of inspiration, solutions and surprises.

Download the magazine now!ASI Automatikk AS Distributor+47 9006 1100