Change Language :

igutex® TX1 - material data

The most important specifications at a glance

igutex® TX1 plain bearings stand for very high load capacity with high radial loads and good abrasion resistance. The special design features long-fibre winding and solid lubricants, ensuring high dimensional stability and lubrication and maintenance-free operation. High dirt and media resistance complete the specification profile.

| Descriptive technical specifications | |||

|---|---|---|---|

| Temperature [°C] | +120 | - 🟧 🟧 ⬜️ ⬜️ ⬜️ + | Max. long-term application temperature |

| Surface pressure [MPa] | 200 | - 🟧 🟧 🟧 🟧 🟧 + | Max. recommended surface pressure at +20°C |

| Coefficient of friction [μ] | 0.1 | - 🟧 🟧 🟧 🟧 ⬜️ + | Best pairing for p = 1MPa, v = 0.3m/s, rotating |

| Wear [μm/km] | 7.10 | - 🟧 🟧 🟧 🟧 ⬜️ + | Best pairing for p = 1MPa, v = 0.3m/s, rotating |

| Price index | - 🟧 🟧 🟧 ⬜️ ⬜️ + |

Permissible surface speeds

Typical applications for igutex TX1 plain bearings are pivoting movements under high loads at relatively low speeds. Irrespective of this, high maximum speeds can certainly be achieved. The speeds stated in the table are limit values for low bearing loads. They do not provide any indication of the wear resistance under these parameters.

Surface speeds of various iglidur materials

| Maximum surface speeds [m/s] | Rotating | Oscillating |

|---|---|---|

| Long-term | 0.4 | 0.2 |

| Short-term | 0.9 | 0.5 |

Permissible pv values

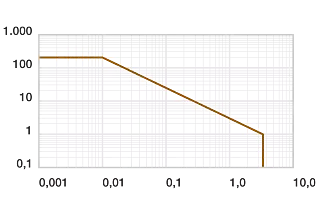

Diagram 01: Permissible pv values for igutex TX1 plain bearings, dry operation against a steel shaft at +20°C

X= surface speed [m/s]

Y = pressure [MPa]

Mechanical specifications

With increasing temperatures, the compressive strength of igutex TX1 plain bearings decreases. Diagram 02 shows this inverse relationship. At the short-term permitted application temperature of +170°C, the permitted surface pressure is still 100MPa. The maximum recommended surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this. Diagram 03 shows the elastic deformation of igutex TX1 under radial loads.

Further information on the load

Friction and wear

It must be noted that a mating surface that is too rough will increase the friction. Shafts that are too smooth also increase the coefficient of friction. We recommend shaft roughnesses (Ra) of 0.4 to a maximum of 0.7μm. The coefficient of friction of the igutex TX1 plain bearings is also highly dependent on the speed and the load. As the surface speed increases, the coefficient of friction also rises rapidly. In contrast, the coefficient of friction decreases continuously with the load.

Shaft materials

In heavy-duty applications, we generally recommend using hardened shafts. This particularly applies when working with igutex TX1. However, acceptable wear rates are also achieved on soft shafts with heavy-duty pivoting of less than 100MPa. The comparison of the wear rate during rotation and pivoting shown in diagram 07 emphasises that the strength of igutex TX1 lies in heavy-duty pivoting.

Chemical resistance

All data at room temperature [+20 °C], + resistant 0 conditionally resistant - non-resistant

| Medium | Resistance |

|---|---|

| Alcohols | 0 |

| Greases, oils without additives | + |

| Hydrocarbons | + |

| Fuels | + |

| Strong alkalines | - |

| Strong acids | - |

| Diluted alkalines | + |

| Diluted acids | + |

Installation tolerances

igutex TX1 plain bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit into a housing machined to a H7 tolerance. After installation in a housing with nominal dimensions, the inner diameter of the bearing automatically adjusts itself as specified in standard cases.

Important tolerances for igutex TX1 plain bearings according to ISO 3547-1 after press-fit, without possible widening of the housing hole:

| Diameter d1 [mm] | Housing H7 [mm] | igutex TX1 plain bearing [mm] | Shaft h9 [mm] |

|---|---|---|---|

| 20 to 40 | +0.000 +0.021 | +0.020 +0.150 | -0.052 +0.000 |

| >40 to 70 | +0.000 +0.025 | +0.025 +0.175 | -0.062 +0.000 |

| >70 to 80 | +0.000 +0.030 | +0.050 +0.200 | -0.074 +0.000 |

Buy igutex TX1 products in the online shop

- Large selection of moulds and materials

- Available within 24 hours

- No minimum order value

- No minimum order quantity

Typical application areas

ASI Automatikk AS Distributor+47 9006 1100